QUALITY

Commitment to Quality by Each Department

At Marusan Co., Ltd., we began as a feed store, and since then we have expanded to the manufacturing and sales of feed and fertilizers, and the raising of chickens, as well as the sales of chicken eggs and liquid eggs.

In order to deliver high-quality products, we maintain farms, factories, feed warehouses, and GP centers. We divide the process across each department, where specialists with a deep commitment and thorough management ensure quality control. We strive to deliver reliable products to all of you.

Main Roles of Each Department

-

Farm Production Department

As a farm that produces safe eggs to deliver to your household, we manage the breeding, rearing, and feeding of chicks, juvenile chickens, and adult chickens.

-

GP (Grading and Packing) Department

In thoroughly sanitized facilities, we wash, dry, inspect, and weigh the eggs before packing them.

-

Liquid Egg Department

In our food factory certified by FSSC22000, we crack eggs and, under strict hygiene management, sort and select them, followed by packaging the liquid eggs.

-

Feed and Fertilizer Department

We handle compound feed and feed rice for poultry, pigs, cattle, horses, and fish farming. Additionally, we handle fertilizers aimed at revitalizing farmland.

Commitment to Quality in the Farm Production Department

To deliver safe and high-quality eggs, we start by rearing healthy chicks.

Animal protein, which is essential for our diet, is also found in eggs. The quality and quantity of this protein are largely determined by the feed given to the chickens.

Therefore, we purchase newly hatched chicks and raise them carefully in the feed department. We use a specially developed feed blend to produce high-quality eggs, while preventing diseases through vaccination with Salmonella SE (Salmonella Enteritidis) vaccines and maintaining hygiene, temperature control, and health management, raising the chicks with care as if they were our own children.

We believe that raising chicks in a good environment is crucial for producing good quality eggs, so we pay special attention to rearing and fostering from the chick stage onward.

We Raise Chickens with a Thorough Management System for Quality Egg Production

High-quality eggs come from healthy chickens that are raised in an environment and with feed that is suitable for them. Our chicken farms are equipped with the latest windless chicken houses, designed to maintain the best possible conditions for the chickens' physiology and comfort while preventing the intrusion of avian diseases and creating a protected environment.

Additionally, we provide our chickens with specially developed blended feed, and all eggs are automatically collected daily by conveyor. By maintaining strict sanitation controls, we ensure the health of the chickens and the quality of the eggs.

To reliably deliver the eggs laid by our healthy chickens to all of you, we conduct feeding and egg collection with a thorough management system every day.

Automatic Egg Collection

To ensure the most hygienic delivery of eggs, automatic collection is conducted via conveyor without human intervention.

Thorough Sanitation Management

Leftover feed or droppings can be a source of bacterial growth, which can affect the health of the chickens. We are always committed to thoroughly cleaning and disinfecting the chicken houses to maintain strict sanitation management.

Thorough Disinfection of Facility Entry Vehicles

To prevent the introduction of external bacteria, we enforce strict disinfection and sterilization procedures for vehicles entering the facility and chicken houses.

Commitment to Quality in the GP Department

We provide high-quality eggs through thorough washing, inspection, and measurement of the eggs.

"GP" is an abbreviation that stands for Grading (sorting) and Packing (packaging). As the name suggests, it refers to the process of sorting and packaging high-quality eggs produced in the farm production department. Starting with the disinfection of Salmonella and other bacteria that are the main causes of food poisoning, the GP department carries out tests for Salmonella bacteria and antibodies, and further inspects and sorts the eggs for cleanliness and cracks, ensuring that only the highest quality eggs are packed and shipped.

Cracked eggs, contaminated eggs, and blood-stained eggs are automatically removed, and the eggs are hygienically packed in cartons or cardboard without human contact.

Thorough Hygiene Management in the Factory to Deliver Safe and Secure Eggs

Delivering safe and secure eggs to our customers requires thorough hygiene management within the factory, which is a critical factor. While the hygiene management of factory equipment is essential, even more attention must be paid to the presence of people entering and exiting the factory. If bacteria or foreign substances are brought in through human movement, we cannot ensure the quality of our products.

At our factory, we have installed a sanitary room at the entrance that uses air pressure to remove dust and debris. We also mandate the disinfection of shoes and handwashing, and we require all personnel to wear sanitized uniforms. This constant hygiene control ensures that our operations are conducted with the highest standards of cleanliness.

Inside the Hygienic Factory

We maintain a factory that is both hygienic and clean, adhering to the national hygiene standards and regulations, as well as the standards for handling food products.

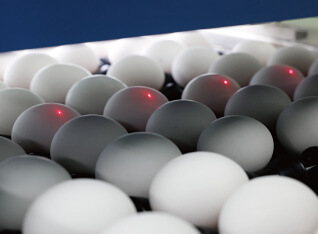

Crack Inspection

Using specialized equipment, we detect and remove small cracks or broken eggs that are not visible to the naked eye. Additionally, infrared rays are used for sterilization.

Dirt Inspection

Each egg is photographed by multiple cameras, and the captured images are automatically analyzed by a computer to detect and remove dirty eggs.

Measurement and Blood Egg Inspection

Using an automatic measuring machine, we measure the weight of the eggs and inspect for the presence of blood or yolkless eggs. Non-conforming eggs are removed, and only conforming eggs are packed.

Packaging

The eggs produced by our company are automatically packaged and labeled under our original brand, "Mukaihara Farm.

Final Inspection

The packaged products undergo a final inspection by human eyes to ensure there are no damages or stains before shipment.

Cardboard Packaging

For both eggs sent to households and eggs shipped to businesses, automatic cardboard packaging is done using machinery.

Product Storage

The high-quality eggs that pass many inspections are managed for hygiene and kept fresh in our product storage facility, where temperature control is carefully managed until shipment.

Commitment to Quality of the Liquid Egg Division

Providing safe and secure liquid eggs requires strict hygiene management and maintaining food safety and quality is paramount!

In factories that consume large amounts of eggs, such as bread factories and food processing plants, liquid eggs are used to save the time and labor involved in cracking eggs.

Strict hygiene management is required during the processing stages before providing the liquid eggs. This includes minimizing human intervention as much as possible by introducing advanced machinery, and taking steps such as sanitizing facilities and equipment, and ensuring workers disinfect themselves before entering work areas.

Additionally, to provide customers with fresh, safe, and secure liquid eggs, we conduct thorough quality inspections at every stage from washing and disinfecting the eggshells to receiving raw materials and shipping.

We also provide liquid eggs of 'Egg White', 'Egg Yolk', and 'Whole Egg'.

Liquid eggs are divided into 'whole egg', 'egg white', and 'egg yolk', and can be utilized according to the customer's needs.

Additionally, customers can choose from various processing methods such as sterilized, non-sterilized, filtered, or unfiltered liquid eggs.

Automatic Egg Breaking

Since liquid eggs require a large number of eggs, the speed of breaking the eggs is also an important factor. We have introduced machines that can break eggs quickly, accurately, and hygienically.

Sterilized Whole Egg Production

Through large sterilization machines that eliminate Salmonella and E. coli bacteria, we process and produce safe liquid eggs.

Automatic Filling into Containers

To provide hygienic and large quantities of liquid eggs, we automatically fill sterilized containers with liquid eggs without human intervention.

Cold Storage and Frozen Warehouse Preservation

Immediately after filling, the products are stored in our fully equipped cold storage and frozen warehouses within the factory. We deliver them to customers through low-temperature logistics.

Commitment to Quality in the Feed and Fertilizer Department

In the Fertilizer Department, we deliver fertilizers for safe and delicious agricultural production, as well as a wide range of other rich fertilizer products.

For livestock and aquaculture businesses, safe and secure feed is indispensable. The majority of the feed we provide is carefully selected imported feed chosen by our specialized staff, who prioritize both quality and price.

To meet our customers' needs, we are constantly keeping an eye on valuable feed information, exchanging insights with local suppliers, and ensuring that reliable feed is imported.

We handle a wide range of feeds for poultry, swine, cattle, horses, and fish, as well as single feed, roughage, and probiotics, delivering them to everyone.

Reliable feed is delivered with our dedicated in-house delivery system.

To ensure that reliable feed is delivered smoothly to many customers, we have established our own warehouse specializing in feed. This system allows us to manage and deliver feed directly from our warehouse. In particular, we take pride in our in-house delivery, where we own our trucks, ensuring that even large amounts of feed can be delivered smoothly. We also have large-wing trucks for efficient loading and unloading.

In the Fertilizer Department, we deliver safe fertilizers, specially crafted for agricultural production, as well as a wide range of other rich fertilizer products.

The fertilizers we handle are mainly from the poultry and liquid egg industries, using eggshells and chicken manure to create specialized eggshell fertilizers, chicken manure fertilizers, and fermented chicken manure pellets. These products are certified by organic certification bodies for use in organic agriculture and are trusted by many farmers. We also handle pure iron, which is effective in preventing root rot in crops.